1 min read

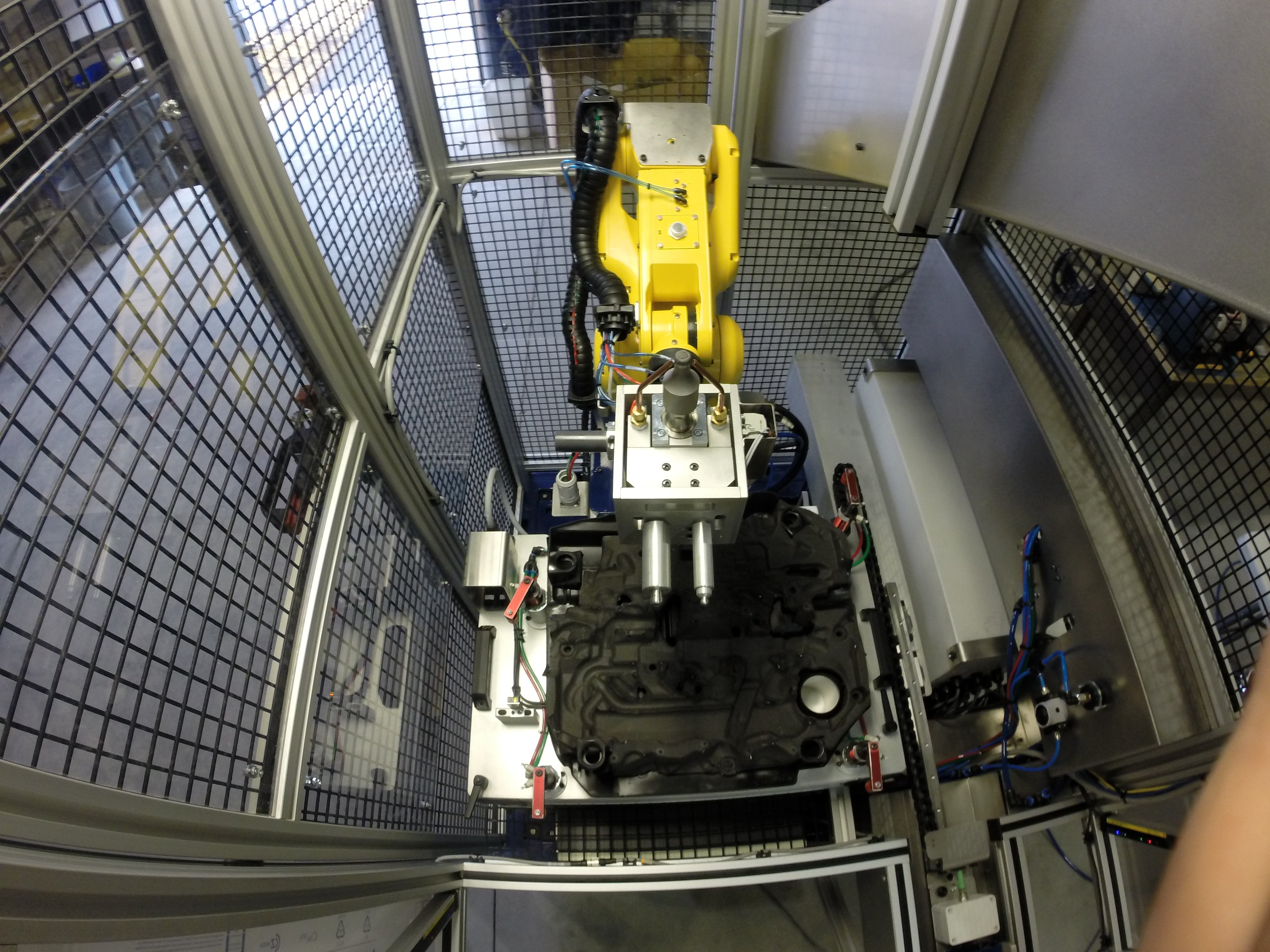

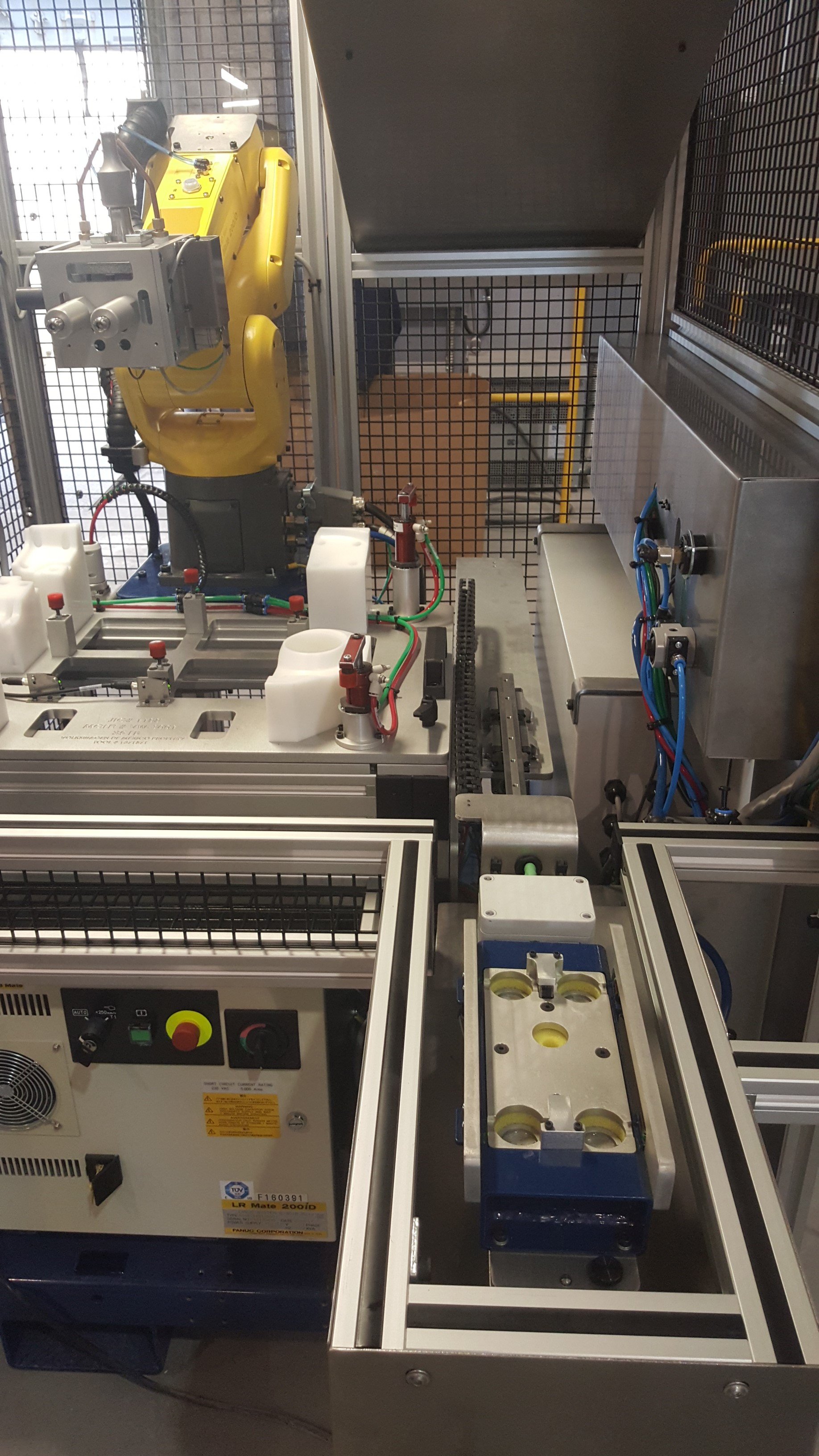

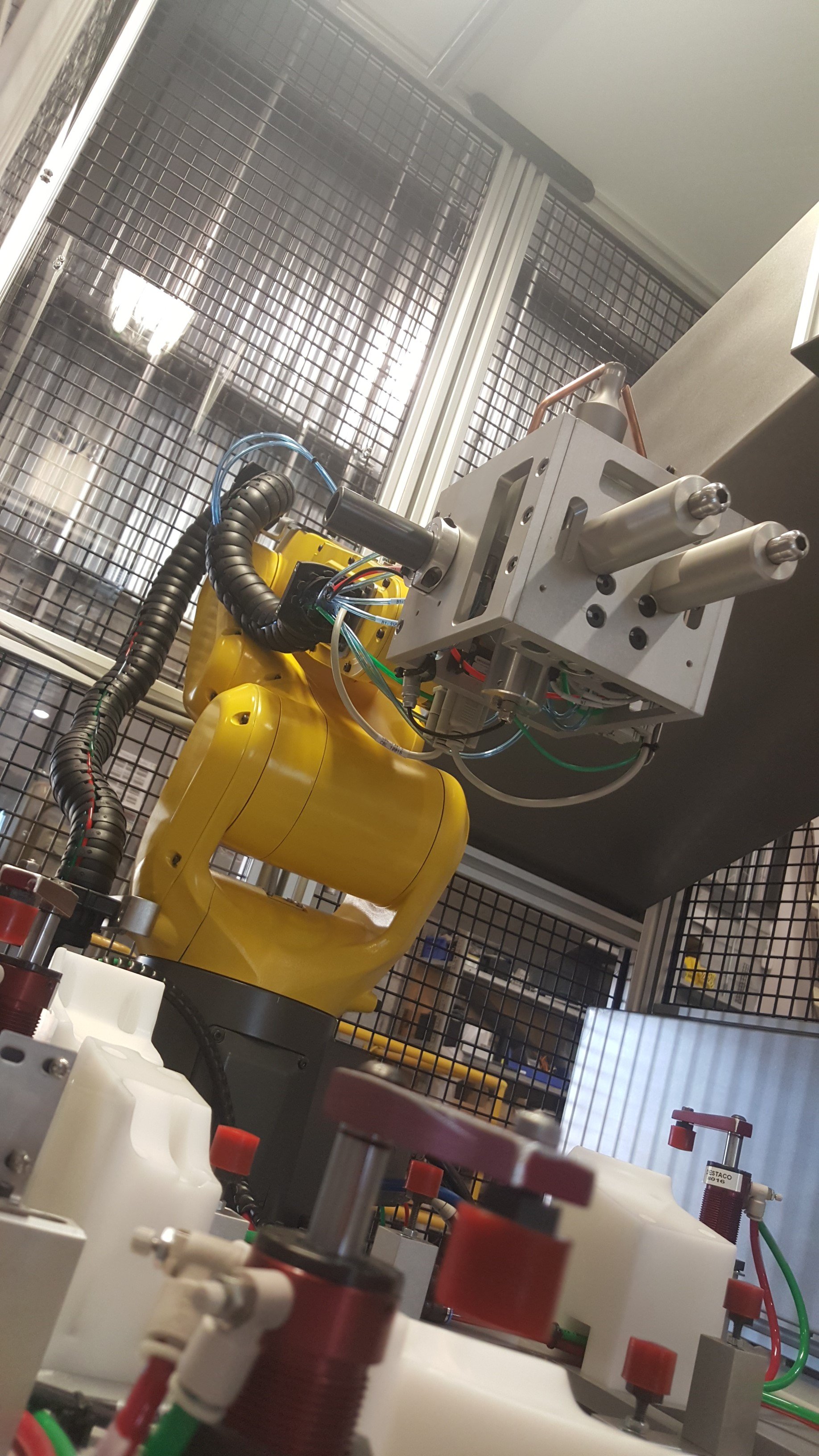

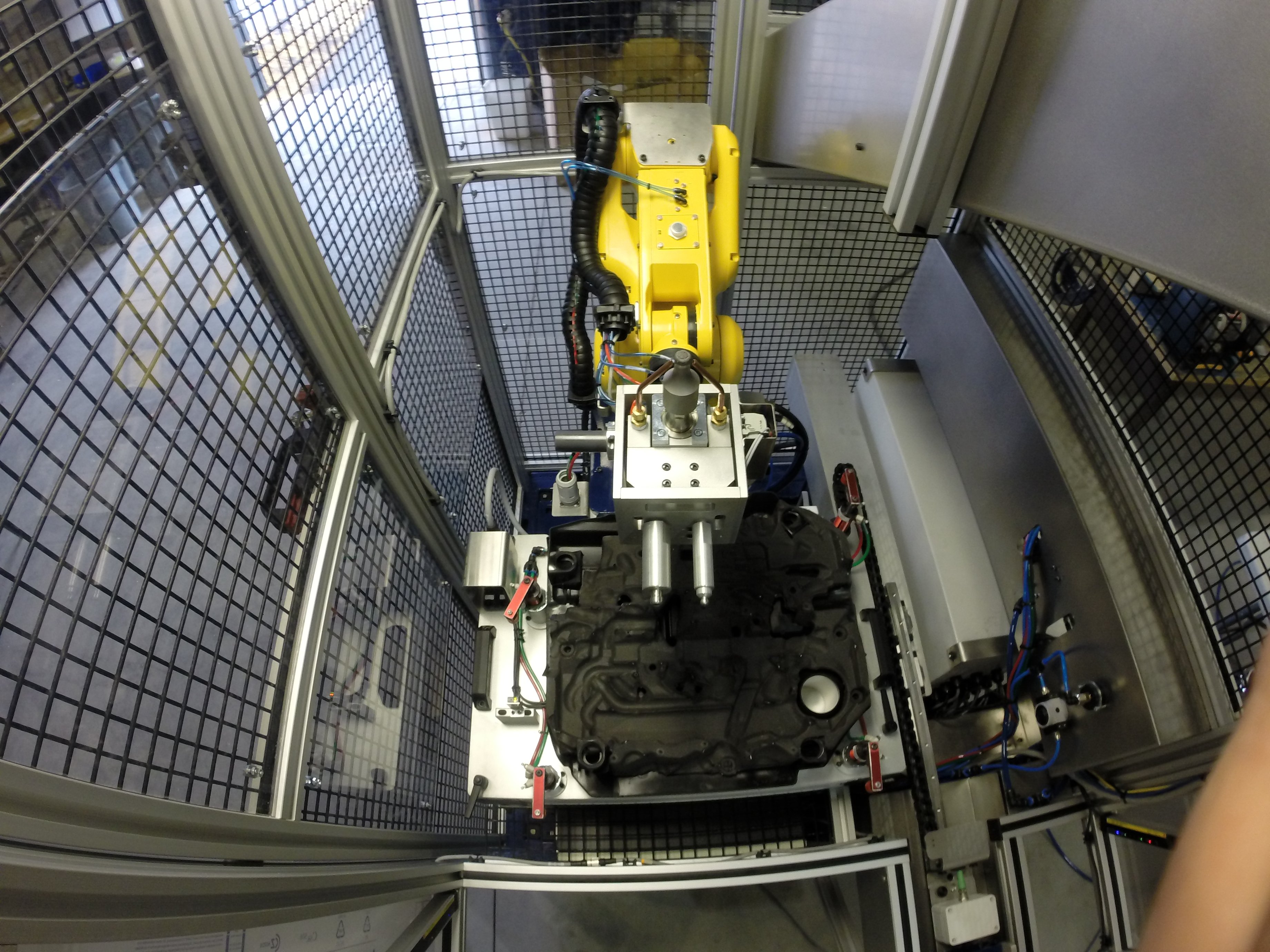

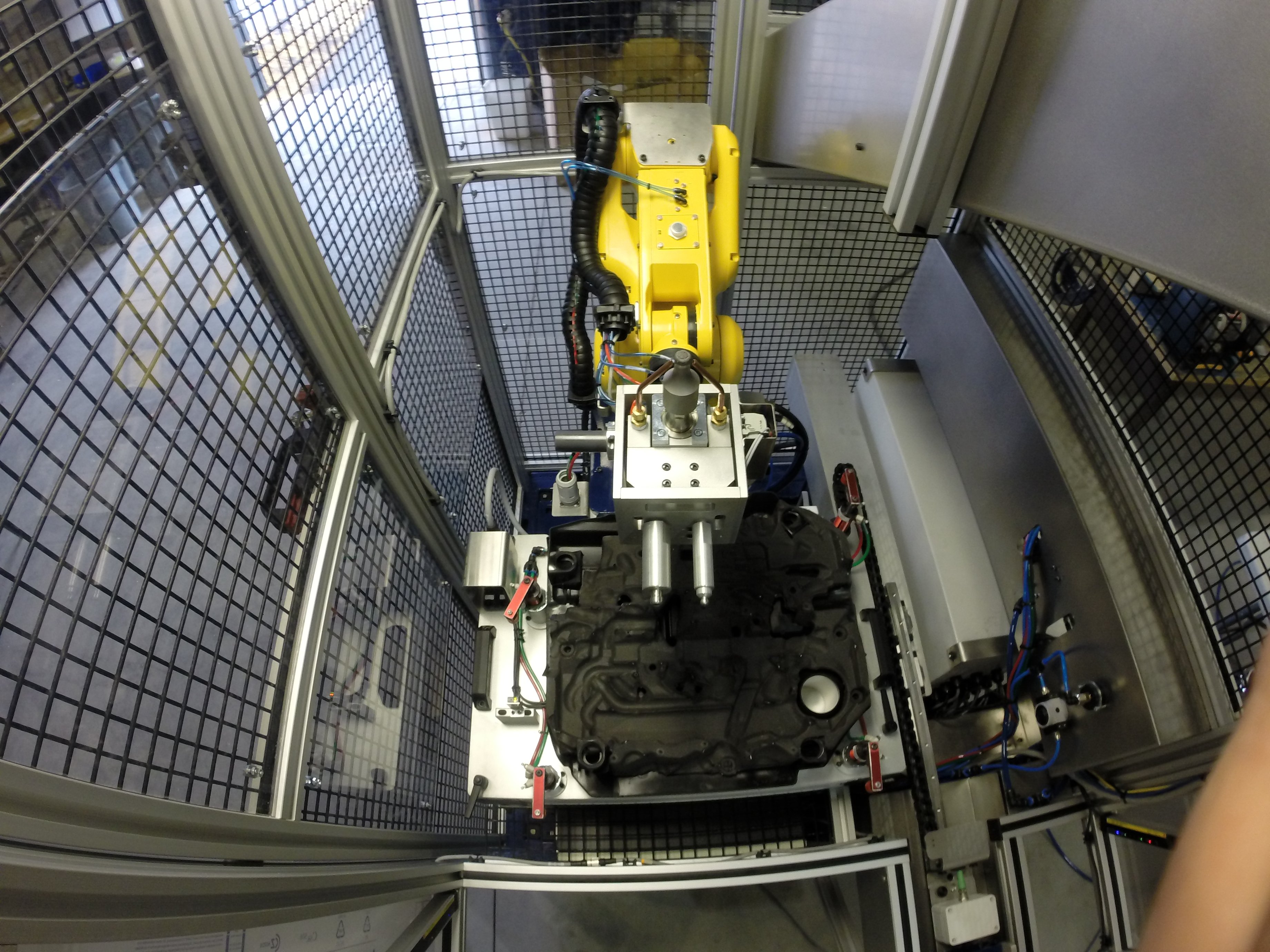

In the context of this project, Systemex Automation carried out the design and assembly of the Volkswagen engine cover cell for the manufacturing in Mexico. This project consisted of manufacturing complete systems with interchangeable modular nests in order to provide the customer with different options according to the production schedule. The manufacturing of these modular nests has a great economic advantage.

In the event that a new product is manufactured, it will be sufficient to develop a new modular base adapted to the leak test systems (already installed in the factory by Systemex Automation), which will save on equipment costs and factory space. The team also installed cameras to guarantee optimal control of the quality of the product according to the established standards.

In addition, a security perimeter was erected around the cell, ensuring protection for the operators and allowing a good view of the operations inside the cell: